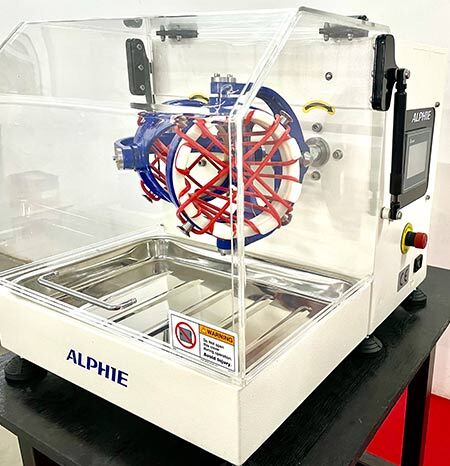

Alphie 10

Alphie mixer are ideal for homogeneous mixing of powder – be it with different bulk density or different proportion of mixing or different shape and particle size.

The best part is, separate and detachable mixing drum / container / bin is loaded inside the mixing cage, meaning no cross contamination and exposure to work environment.

Typical applications

It is ideal for use in R & D laboratories, educational institutes, small batch production industry, food/nutrition, pharmaceuticals, metal powder, resin and plastic powder, Nano powder, IOL Polishing, Diamond tool powder, bakery, spices, concentrates and many more applications.

Construction

- Standard mixers are built with structure made from Carbon steel. While the container holder is from Heat Treated high grade Aluminium alloy. They are powder coated material after surface preparation.

- We also offer GMP design where all exposed parts are made from stainless Steel AISI 304 material.

Mixing drum is removable

- The best feature of the Alphie mixer is that – the mixing drum is removable. So, the powder does not go to the mixer. But the powder filled and sealed container goes to the mixer. And hence, there is no chance of powder being exposed to the atmosphere while using the mixer.

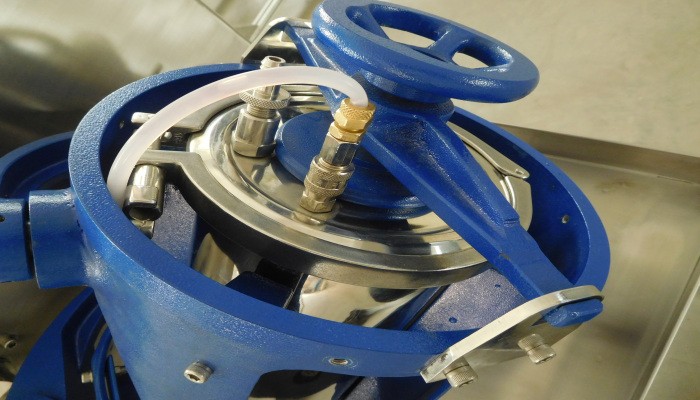

- Another advantage is, the mixing container material can be supplied to suit your application – Stainless steel / Plastic / Glass / Gun Metal / Aluminium etc.

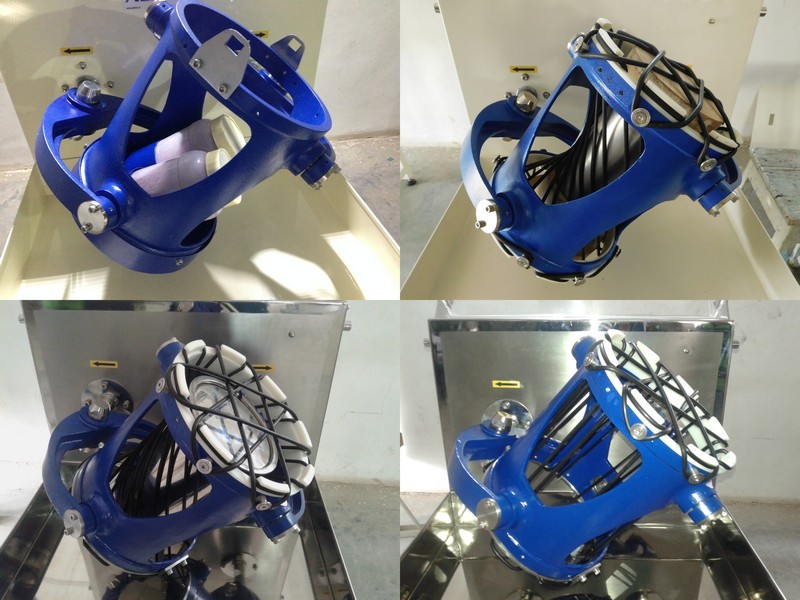

Ability to fit any smaller shape / size / material of container:

- Mixer comes with Crown – Rubber string attachment which makes it possible to hold any smaller shape / size / material of container.

- Mixer can be supplied with a holder to accommodate more than one container.

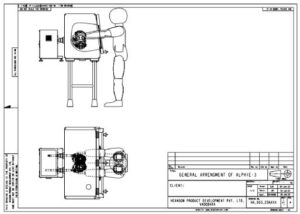

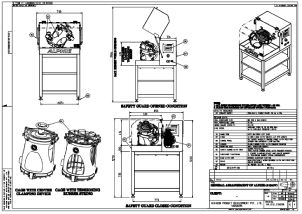

Mixer with its base stand

- Alphie 10 is supplied fitted on its own working table. It has its levelling feet and sturdy structure. It does not need any further anchoring or fixing.

Plug and play operation

- Alphie 3 Mixer runs on single phase power (we offer country specific power supply). This is a simple table top mixer and needs only 5A socket.

Maintenance free design

- Mixer is constructed with state of the art technology without use of belt or chain or even bearing re-lubrication. This makes it perfect maintenance and attention free operation.

Safety guard and removable tray

- Mixer has front Plexi-glass safety guard with interlock. The mixer shall stop, if the guard is opened and mixer can not start unless the guard is closed.

- Mixer has a removable Stainless Steel tray below rotating drum to collect accidental seepage.

Fixed stop position –

- After cycle completion, mixer stops at predefined position on its own for easy drum loading and unloading. No need to manually rotate to bring correct position.

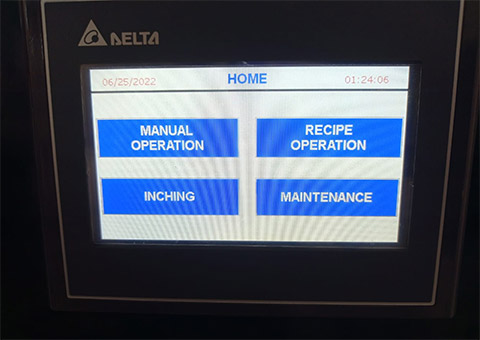

Control panel

- Alphie 3 mixer is built with HMI / PLC panel and Variable Frequency Drive (VFD) as standard supply. User can set the Container Speed, Mixing time and Mixing direction.

- Mixer panel is programmed with the ability to set mixing in forward direction for some part of mixing cycle and in reverse direction in other part of cycle time. This is especially beneficial for mixing diverse density material.

- Mixer has Recipe mode, where speed and time can be set with password protection.

- Our control panels are built accordance to CE certification.

Operator Friendly Panel Features

- Mixer automatically stops at home/container loading position following completion of each mixing cycle.

- Actual process times, set speeds and direction of rotation are clearly indicated during mixing cycle.

- Mixing cycle can be paused/resumed at any time without loss of parameters.

- Mixer comes at the pause state when safety guard is opened.

- Operator can resume the batch without loss of parameters when safety guard is closed.

- PLC retains time remaining value upon start-up following power failure and/or e-stop event to resume blending seamlessly.

Life long access to documents from our web server

- QR code pasted on machine name plate for scanning

- Life long access to the technical documents in soft copy

- Access to the Video training instructions

- Download operating manual wiring diagram etc.

Mixing containers

- Choose from varieties of mixing containers from stainless steel, Aluminum, Plastic, Glass, Gun Metal etc.

- Stainless steel containers are offered in AISI 304 as well as AISI 316L material with silicone gasket.

- We offer holders where multiple containers can be fitted.

Option of injecting liquid while mixing

- As an optional feature, Alphie 10 can be constructed to have provision to inject liquid in the mixing chamber while mixer is running. A pre defined quantity of liquid at required interval can be inserted in mixing container without stopping the mixer.

Option of mixing in controlled atmosphere using glove box/isolator (+ve or -ve pressure) mixer stand

- Alphie 3 can be designed and manufactured so the mixing drum can remain in the Glove box/Isolator and drive part remain outside.

Option of control panel with 21 CFR, part 11 compliance

- We can supply mixer for Pharmaceutical industry complying the 21 CFR regulatory requirements.

Specifications

Note : Model offered in Powder coated Carbon steel and Stainless Steel GMP construction.

| Capacity (Ltr) | 10 |

| * Effective Capacity @ 80% (Ltr) | 8 |

| Max mixing mass (kg) | 15 |

| Motor Power | 0.5 hp |

| Power Supply (suitable to your country standards) | Single phase, 110/220 V |

| Container Revolution (rpm) | 10 – 70 |

| Max Container Size | Dia 220 mm X 350 mm Long |

| Machine Weight (kg) | 120 |

* It is advisable to keep min. 20% empty volume in mixing container for better mixing.

- What should be the correct mixing speed? It is not correct to assume that running at high speed will do fast and better mixing. In many applications, high speed gives adverse mixing results. In normal mixing cases, mixing at 50% of maximum permissible speed should be sufficient to start with.

- How much should I fill the material in mixing bottle?It is always good not to fill more than 70% of bottle total volume. We recommend filling upto 40 – 50%. Mixing time increases exponentially when filled more than 50% of volume.

- Is there any preference on mixing direction? Should i rotate the bottle in clockwise or anti clockwise direction? – There is no preference or rule of mixing direction. You can rotate in any direction suitable to you. However, few of the customers have got better and quicker mixing results when rotated in one direction for half the time and in opposite direction in remaining half batch time.

- How long should I mix?This depends on many variables like % of bottle filled, powder condition etc. However, most applications start getting results in 5 to 15 minutes. Its a myth that more mixing gives better homogeneity.

- Is there any shear force acting while mixing?Alphie mixer runs on the principle of kinematic inversion. So, the bottle does not rotate, but it inverts. So this is theoretically zero shear force mixing.

- Can Alphie be used for liquid mixing also?Yes, Alphie can be used for powder, liquid and suspensions.

- What is the material of mixing container suitable for my application? – Stainless Steel AISI 304 is material suitable for most application. If application is Pharmaceutical or Food; AISI 316L is used. We offer Aluminum / Gun metal containers for explosive powder mixing; Plastic containers are good for other many applications

- What is the material of container fixing rubber bands? The rubber bands are made from Silicone

- Do I need to keep spares of rubber strings? As such, the strings are sturdy enough to live long. We also keep stock of the same in case you need them in emergency.

- Does Alphie 10 needs grouting or foundation?No. Alphie 10 is supplied with a table. You just keep on flat surface and level it by levelling pads of mixer.

- Can we add balls in mixing container?Yes, suitable size stainless steel or other material balls can be added. They can be sourced from us also.

- Is there any grease / lubrication required in the Alphie, even after one year?No, Alphie 3 is built with life long lubricated joints. All the bearings are sealed and so does not need any re-lubrication.

- How can I learn more about how to use this mixer?Mixer is supplied with Instruction Manual copy placed inside the tray. Further, a QR code sticker has been placed on the body of mixer near its name plate. Scanning it, will take you to the video of how to use this mixer.

- Do you send CE certificate and other documents with the mixer?Yes, if your mixer is supplied as CE compliance mixer; certificate shall be sent along with the mixer. All mixers are marked with QR code, scanning which you can find all related documents and operating video.

- Can you supply mixer complying CE requirement?Yes, Alphie 10 can be supplied complying the CE requirements.

- Can I buy more containers?Yes, you can plan to buy while purchasing the mixer or can buy later also separately. We keep stock of all size of bottles with us.

- How smaller container can be fitted in the Alphie 10? Alphie 10 is supplied with Crown – Rubber string attachment. It is capable to fit any smaller container of any shape and material. It can fix even a 01 Ltr container also.

- I am not staying in India. How can you give me after sales support?Our team is available all the time to respond your query and give online support for any of your queries. Further, we have developed video instruction for most of trouble shooting which customer can do on his own.

- How can I scale up my laboratory results for production requirements? We have developed a program where placing R & D mixer data can generate the speed and time required for larger capacity mixer. As per example, if you have run Alphie 3 for 30 minute and 50 rpm – at what speed and how much time should I run 200 Ltr Mixer.

Scale Up

With the similar geometry of mixing container and a variable mixing time & container revolution, Alphie blender easily meets the fundamental requirements to scale up to pilot and production sizes from the laboratory volume.

For the similar property and nature powder blend, the scaling up is possible only by ensuring:

- The % of filling volume (powder filled volume to total container volume)

- The number of container revolutions and mixing time

- The Froude number (dynamic scale factor)

An example of scaling up:

Experimenting in our 3 Ltr Alphie mixer with following parameters:

- For 10 minutes.

- At 60 RPM.

The same blending quality can be obtained in the Alphie mixer of 100 litres with the following conditions:

- For 18 minutes.

- At 33 RPM.

Leave a Reply