For the explosive/ammunition/fireworks powder homogeneous mixing solution, Alphie Mixers are offered with ‘Extended Shaft (ES)’ series design.

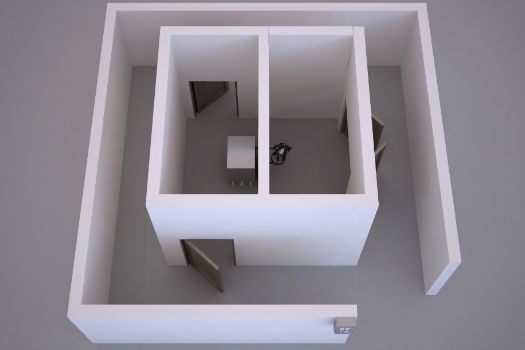

Mixer is manufactured and installed, so that the drive unit and the mixing unit are separated by a partition wall. So, the mixer machine Flameproof motor, gearbox and drive unit remains on the back side of the partition wall and the mixing unit comes on the other side. Exposed parts in mixing room are made of Non Ferrous material like Aluminum, Brass etc.

The mixing results are incomparably superior and faster than conventional hand mixing or traditional mixers. Safe mixing operation is ensured, as powder is filled in closed container and so it is not an open air mixing. And the best part is, this is operator friendly machine, needing no special training.

Construction

- Hexagon offers ‘Extended Shaft (ES)’ series for the Explosive/Fire cracker powder homogeneous mixing solution.

- Mixer is manufactured, so that the drive unit and the mixing unit are separated by a partition wall. So, the mixer’s drive unit remains on the back side of the partition wall and the mixing unit comes on the other side.

- Drum Holder is made of High grade Aluminium Alloy heat treated casting with Dynamically balanced rotating parts. Shafts are made of high alloy steel with corrosion resistance coating fitted with sealed beaerings.

Mixing drum is removable

- The best feature of the Alphie mixer is that – the mixing drum is removable. So, the powder does not go to the mixer. But the powder filled and sealed container goes to the mixer. And hence, there is no chance of powder being exposed to the atmosphere while using the mixer.

Ability to fit any smaller shape/size/material of container:

- All the mixers are designed in such a way, that smaller size/shape of container can be accommodated. Even, one can fit more than one containers also in the space.

- Suitable container holders can be supplied along with the mixer, so the drum is held firmly in the mixer and does not shift/move.

Mixer installation

- Alphie mixer is sent in the Knocked-Down condition. Mixing drum is assembled at site after the partition wall is constructed and drive unit is

anchored on other side of the wall. Alphie mixer are supplied with Flame proof construction electric motor (ATEX can be offered as optional) along with FLP safety switches for the door. Machine can be started only when the mixing room is closed and operator has come out from it. - For Fire cracker applications, Alphie mixers are designed as per norms of PESO. We can supply mixers as per other regulatory standards also.

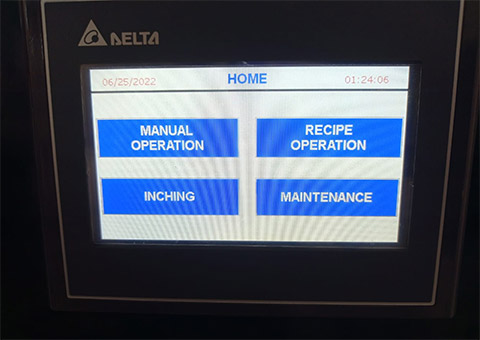

Control panel

- Alphie mixers are built with Timer and Variable Frequency Drive (VFD) as standard supply. User can set the Container Speed and Mixing time.

- Mixer panel is programmed with the ability to have all safety interlock in the place to avoid any accident.

- Our control panels can be built accordance to CE certification when required.

Operator Friendly Panel Features

- Mixer automatically stops at home/container loading position following completion of each mixing cycle.

- Actual process times, set speeds and direction of rotation are clearly indicated during mixing cycle.

- Mixing cycle can be paused/resumed at any time without loss of parameters.

- Mixer comes at the pause state when safety guard is opened.

- Operator can resume the batch without loss of parameters when safety guard is closed.

- PLC retains time remaining value upon start-up following power failure and/or e-stop event to resume blending seamlessly.

Life long access to documents from our web server

- QR code pasted on machine name plate for scanning

- Life long access to the technical documents in soft copy

- Access to the Video training instructions

- Download operating manual wiring diagram etc.

Mixing containers

- Choose from varieties of mixing containers from stainless steel, Aluminium, Conductive Plastic, Gun Metal etc.

- Stainless steel containers are also offered in AISI 304 as well as AISI 316L material with silicone gasket.

- We offer holders where multiple containers can be fitted.

Option of injecting liquid while mixing

- As an optional feature, Alphie mixer can be constructed to have provision to inject liquid in the mixing chamber while mixer is running. A pre defined quantity of liquid at required interval can be inserted in mixing container without stopping the mixer.

| Specifications | A 10 ES | A 20 ES | A 35 ES |

|---|---|---|---|

| Mixing Capacity (Ltr) | 10 | 20 | 35 |

| Power Supply (suitable to your country standards) | Single phase, 110/220 V, 50 Hz | Single phase, 110/220 V, 50 Hz | Single phase, 110/220 V, 50 Hz |

| Motor Rating | 1 hp | 1 hp | 1 hp |

| Mixing Container size (Dia D x Height H) | Dia 221 * 360 H | Dia 265 * 410 H | Dia 310 * 550 H |

| Max Drum Rotating speed (RPM) | 70 | 50 | 40 |

| Machine Weight (kg) | 185 | 250 | 325 |

- What is special construction for Explosive Powder Mixing? As initially developed for Fire crackers application in India, ES series mixers are supplied in knocked down condition. The mixer is assembled in Wall-Through construction where the mixing drum is in one room and electric motor is in another room. All exposed parts are made from Non Ferrous material in the mixing Room.

- How much should I fill the material in mixing bottle? It is always good not to fill more than 70% of bottle total volume. We recommend filling upto 40 – 50%. Mixing time increases exponentially when filled more than 50% of volume.

- What should be the correct mixing speed? It is not correct to assume that running at high speed will do fast and better mixing. In many applications, high speed gives adverse mixing results. In normal mixing cases, mixing at 50% of maximum permissible speed should be sufficient to start with.

- Is there any preference on mixing direction? Should i rotate the bottle in clockwise or anti clockwise direction? – There is no preference or rule of mixing direction. You can rotate in any direction suitable to you. However, few of the customers have got better and quicker mixing results when rotated in one direction for half the time and in opposite direction in remaining half batch time.

- How long should I mix? This depends on many variables like % of bottle filled, powder condition etc. However, most applications start getting results in 5 to 15 minutes. Its a myth that more mixing gives better homogeneity.

- Is there any shear force acting while mixing? Alphie mixer runs on the principle of kinematic inversion. So, the bottle does not rotate, but it inverts. So this is theoretically zero shear force mixing.

- Can Alphie be used for liquid mixing also? Yes, Alphie can be used for powder, liquid and suspensions.

- What is the material of mixing container suitable for my application? We offer Aluminum/Gun metal containers for explosive powder mixing. If required, we can offer conductive polymer/Rubber material also for specific requirements.

- How can I fit smaller containers in mixer? We can supply suitable design adapters for fixing smaller container in Alphie mixer. If you are planning to fit say 5 Ltr container in Alphie 20; we shall supply fixing adapter for it along with the mixer.

- Does big capacity Alphie mixer needs grouting or foundation? Mixers supplied upto 35 Ltr are supplied with self levlling pads. You just keep on flat surface and level it by levelling pads of mixer. Mixers 50 Ltr and above can be grouted.

- Can we add balls in mixing container? Yes, suitable size stainless steel or other material balls can be added. They can be sourced from us also.

- How can I learn more about how to use this mixer? Mixer is supplied with Instruction Manual copy placed inside the tray. Further, a QR code sticker has been placed on the body of mixer near its name plate. Scanning it, will take you to the video of how to use this mixer.

- Do you send CE certificate and other documents with the mixer? Yes, if your mixer is supplied as CE compliance mixer; certificate shall be sent along with the mixer. All mixers are marked with QR code, scanning which you can find all related documents and operating video.

- Can you supply mixer complying CE requirement? Yes, Alphie 10 can be supplied complying the CE requirements.

- Can I buy more containers? Yes, you can plan to buy while purchasing the mixer or can buy later also separately. We keep stock of all size of bottles with us.

- I am not staying in India. How can you give me after sales support? Our team is available all the time to respond your query and give online support for any of your queries. Further, we have developed video instruction for most of trouble shooting which customer can do on his own