How one of the world’s leading manufacturer of fragrances solved their inefficient mixing problem

Application

One of the leading manufacturers of fragrances in the world was looking for a mixer to mix 0.1% fragrance oil to a detergent powder, for research and development, across small batches from 20 grams to 1 kg and more.

Challenge

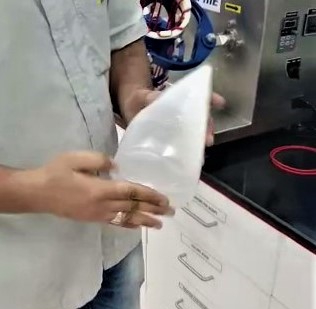

The current process involved manual mixing in a plastic bag for long duration. Conventional 2 dimensional mixers like Sigma were not able to mix the fragrance oil uniformly with the detergent. And due to inefficient mixing, the fragrance could not last longer on the fabric, after every fabric wash cycle. Also, the manual process resulted in inconsistent batch every time and created a dependency on the skill of the mixing operator.

Solution

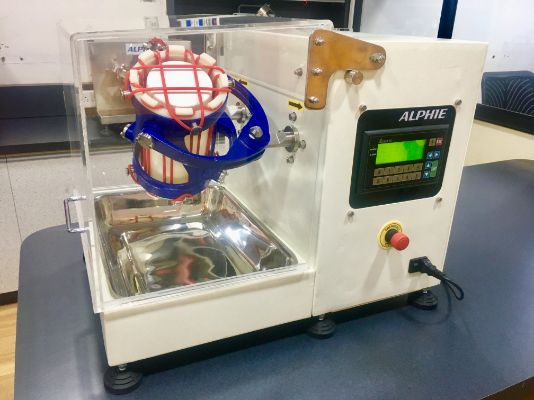

We were contacted to help solve the problem. A trial was arranged on Alphie 3 litre capacity, laboratory scale, 3 D Mixer. Various batch sizes from 20 grams to 1 kg were mixed at different rpm ranging from 25 to 75. The challenge was to get uniform distribution of fragrance oil across the detergent powder – for long lasting fragrance – even after heavy duty wash and dry cycle.

The mixing process on Alphie 3 Mixer began with weighing the batch of powder on the laboratory weighing scale and adding fragrance oil by perfume smelling strips as per the dosage of 0.1%. The batches were then mixed in forward direction for 5 minutes and in reverse directions for 5 minutes and at average revolutions per minute of 45. The batch was smell tested by a perfumer and found to be efficiently mixed on random samples drawn while mixing.

Manual mixing method used earlier

inconsistent batch.

The batch got efficiently mixed with Alphie 3.

Leave a Reply